KinetiX - 10X SUPEROXALLOY ABRASIVES

SOLVES, BIG, COMPLEX PRODUCTION CHALLENGES

Choose KinetiX superoxalloy abrasives for…

• Large production and maintenance jobs

• Shipyards

• Bridges

• Tanks

• Pipelines

• Rail

Need for speed in volume:

- Big projects with tight, rigid production timetables

- Work schedules with no time allowance for post-blast cleaning or rework

- Settings where poor worker visibility caused by abrasive dust reduces speed (and quality)

- Critical assets back online faster

- Eliminate hand-tooling ahead of blasting

Need for speed in volume:

- Uniform surface profile across expansive areas

- Environments where low visibility from abrasive dust could

- compromise craftsmanship

- Ultra-clean jobsite required

- Delayed rust bloom and low-to-no embedment

- Tackle more jobs per year through increased productivity

Difficult-to-remove coatings:

- Remove thick coatings, elastomerics, multi-layers, two-part epoxies, fusion bonded, polyurea, tank liners, marine coatings and more

Reducing total job cost:

- Jobs of sufficient scale—where increased speed and reduced abrasive consumption can deliver payback in reduced cost per sq. ft.

- Reduce rework from embedment, rust bloom and coating failure

Safety:

- Exceptional worker safety

- Exceptional environmental safety: air and water quality - Can be harmlessly left on the ground or in water (TCLP)

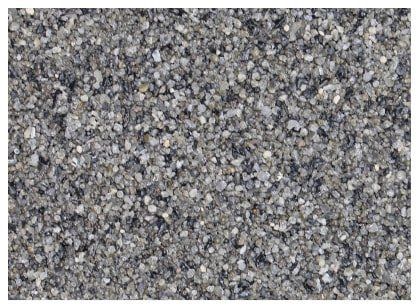

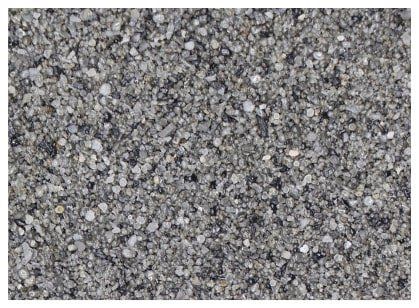

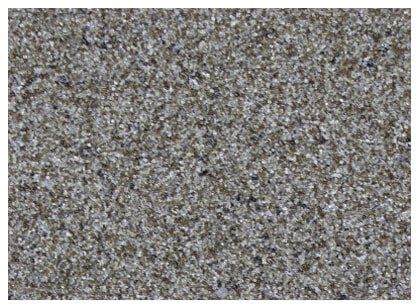

kinetiX Grades

Kinetix Packaging Options

• Bulk loads

• 4,000 LB. Supersacks

• 2,000 LB. Supersacks

• 100 LB. bags

• 50 LB. bags

+ KinetiX Optimization Guide Download

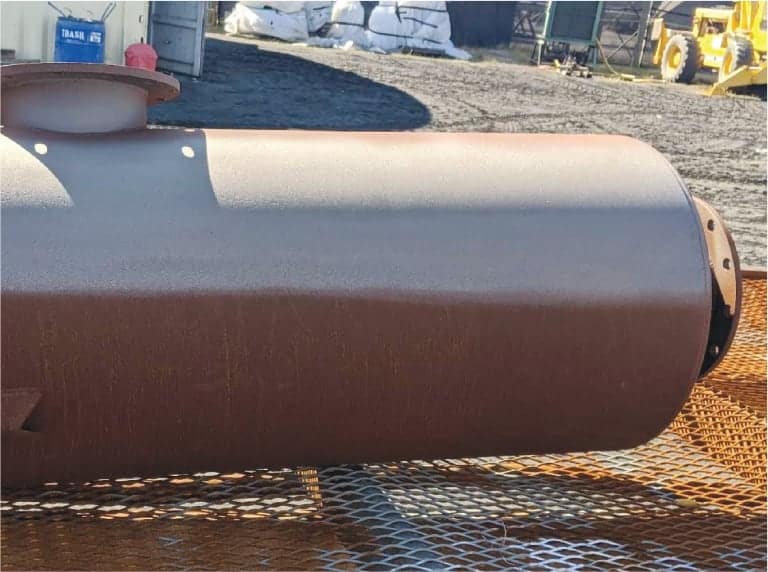

KinetiX superoxalloy abrasive on the job

KinetiX Ordering Information

| STOCK # | Grit SIZE | Surface Profile | Packaging | Reusability @100PSI | Bulk Density |

|---|---|---|---|---|---|

| KX1020 | 20/40 Mesh | 2.5 - 4.0 mil | Bulk Load | 2-4 times | 90-95 lb/ft3 |

| KX1022 | 20/40 Mesh | 2.5 - 4.0 mil | 4,000 lb SuperSack | 2-4 times | 90-95 lb/ft3 |

| KX1023 | 20/40 Mesh | 2.5 - 4.0 mil | 2,000 lb SuperSack | 2-4 times | 90-95 lb/ft3 |

| KX1024 | 20/40 Mesh | 2.5 - 4.0 mil | 100 lb Bags | 2-4 times | 90-95 lb/ft3 |

| KX1028 | 20/40 Mesh | 2.5 - 4.0 mil | 50 lb Bags | 2-4 times | 90-95 lb/ft3 |

| KX1030 | 20/70 Mesh | 2.5 - 3.5 mil | Bulk Load | 2-6 times | 93-103 lb/ft3 |

| KX1032 | 20/70 Mesh | 2.5 - 3.5 mil | 4,000 lb SuperSack | 2-6 times | 93-103 lb/ft3 |

| KX1033 | 20/70 Mesh | 2.5 - 3.5 mil | 2,000 lb SuperSack | 2-6 times | 93-103 lb/ft3 |

| KX1034 | 20/70 Mesh | 2.5 - 3.5 mil | 100 lb Bags | 2-6 times | 93-103 lb/ft3 |

| KX1038 | 20/70 Mesh | 2.5 - 3.5 mil | 50 lb Bags | 2-6 times | 93-103 lb/ft3 |

| KX1040 | 40/70 Mesh | 2.0 - 3.0 mil | Bulk Load | 4-6 times | 95-105 lb/ft3 |

| KX1042 | 40/70 Mesh | 2.0 - 3.0 mil | 4,000 lb SuperSack | 4-6 times | 95-105 lb/ft3 |

| KX1043 | 40/70 Mesh | 2.0 - 3.0 mil | 2,000 lb SuperSack | 4-6 times | 95-105 lb/ft3 |

| KX1044 | 40/70 Mesh | 2.0 - 3.0 mil | 100 lb Bags | 4-6 times | 95-105 lb/ft3 |

| KX1048 | 40/70 Mesh | 2.0 - 3.0 mil | 50 lb Bags | 4-6 times | 95-105 lb/ft3 |