10X SUPEROXALLOY ABRASIVES

Which superoxalloy abrasive is right for the job?

Delivering breakthrough performance

Ultra Safe

• SSPC-AB 1 Class A (Less than 0.1% Free Silica)

• Extremely Low Dust

• Sustainable 100% Recycled Material

Ultra high-performance

• Removes difficult coatings

• Performs multiple steps in one

• Delays rust bloom

Ultra low-consumption

• Less abrasive required

per job

• Perform more work per pot

• Lower surface prep cost per sq. ft.

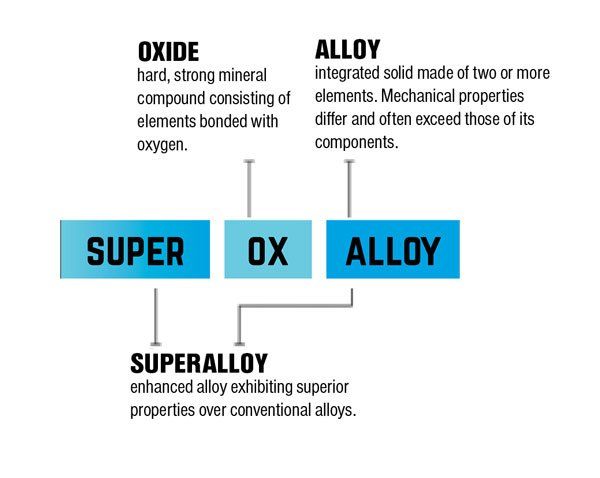

What are superoxalloy abrasives?

Supeoxalloy

(soo-per-ox-uh-loy)

An engineered alloy of oxide minerals created through highly

controlled formulation and tempering (high heat + rapid cooling).

The process creates non-crystalline (amorphous) particles that resist breakage under stress of high-speed mechanical impact.

[ From metallurgy/minerology: superalloy + oxide ]