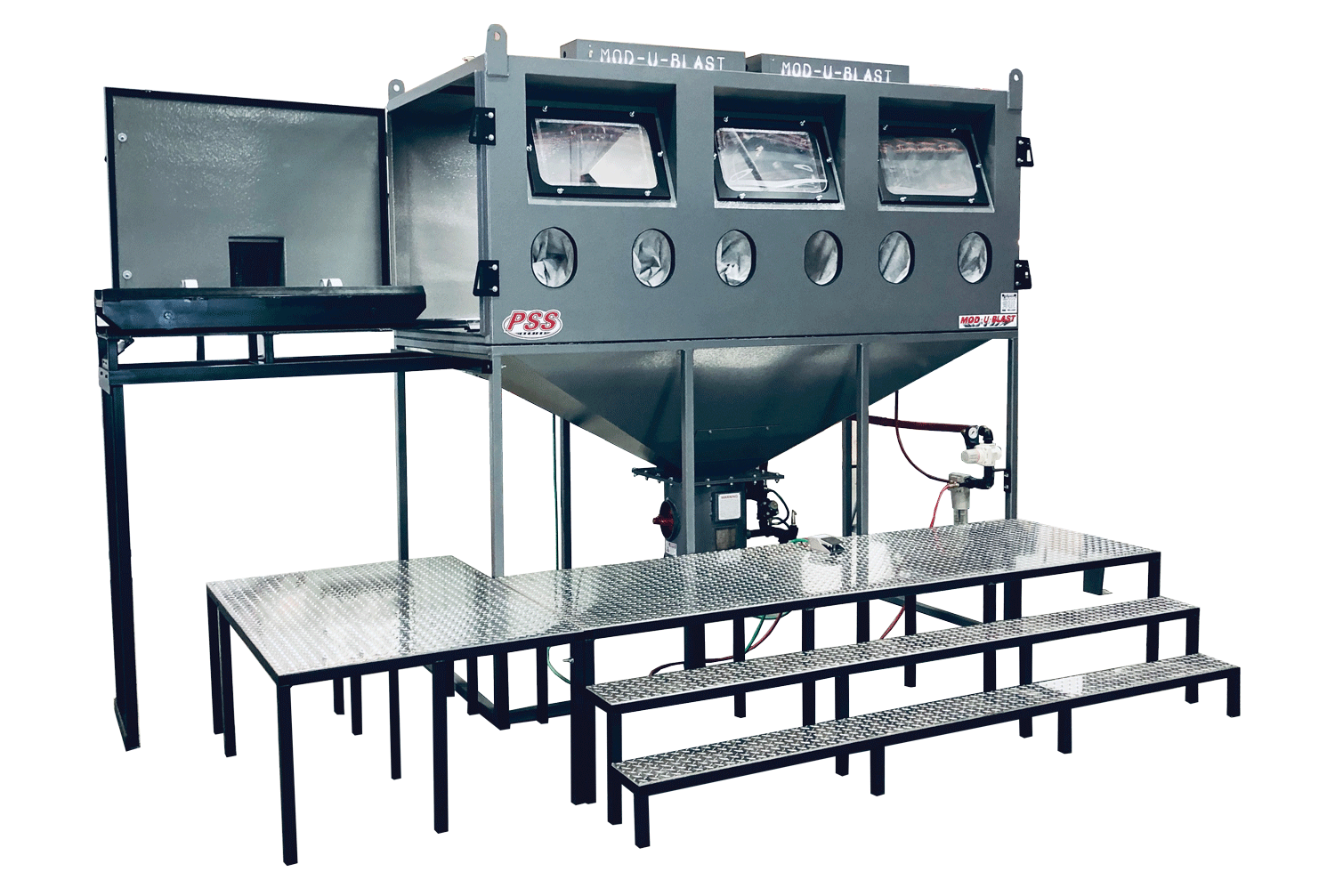

PSS-Series

DIRECT PRESSURE SHOT BLAST CABINETS

- PSS-Series machines

are designed for use with abrasives with a bulk density of 130 or higher, typically steel shot or grit. Lighter abrasives such as garnet, stone blast, ferric oxide, aluminum oxide can be used however these lighter abrasives are more effectively utilized in our Industrial P (Pressure) and S (Suction) Series Machines.

- PSS-Series machines are built to withstand the rigors of heavy blast media. Sprayed with a poly urea coating, this machine is the right solution for any peening application whether for stress relief, oil retention, cleaning or finishing purposes.

- The pressure vessel is positioned below the feed hopper because heavy medias cannot be picked up by using pneumatic reclaimers. Media drops directly into the pot, through an appropriately sized screen for re-use. The Mod-U-Blast® 300, 600 or 900 CFM blower/separator assembly removes dust and maintains optimum visibility in the cabinet.

- Internal abrasion resistant urea spray lining

- 12 gauge steel (1/8” rubber in loading hopper section)

- Tungsten blast nozzle

- Heavy 1/4” perforated steel floor

- Air blow-off gun

- Operator step-up station platform

- Polycarbonate safety window (quick change frame system)

- Optimum Mod-U-Blast® foot valve

- External lighting system

- Powder coated for durability

- Auto control system

- Special grit valve for metering and flow precision

- Moisture separator, regulator and gauge

- Open front for easy maintenance and hopper access

- Overlapping positive tension doors

- Safety door shut offs

| Nozzle | Bore Size | CFM@60PSI |

|---|---|---|

| 2 | 1/8" | 22 |

| 3 (standard) | 3/16" | 49 |

| 4 | 1/4" | 90 |

| 5 | 5/16" | 148 |

| 6 | 3/8" | 197 |

| 7 | 7/16" | 265 |

PSS-SERIES CABINET OPTIONS

Available with inside and/or outside track assembly or as set-in turntable only. Standard turntables hold up to 700 lbs, custom turntables hold up to 2000 lbs. Mod-U-Blast’s turntable systems will increase worker convenience, comfort and productivity while decreasing glove wear, hand injuries and overall operator fatigue. Ideal for blast cleaning larger, heavier components. May be furnished for one (1) or both (2) sides of the blast cabinet.

Custom Pass through kits available for new or existing Cabinets.

Save time and discomfort blasting pipe with Mod-U-Blast’s Pipe Rolling Carts.

| Stock # | Description | Working Chambers (W"xD"xH") | Estimated Shipping Weight (lbs.) |

|---|---|---|---|

| PSS3636-3B | CABINET 300 CFM BLOWER & BAG | 36” x 36” x 40” | 683 |

| PSS3636-3F | CABINET 300 CFM BLOWER & FILTER | 883 | |

| PSS3636-3FH | CABINET 300 CFM BLOWER. & HOPPER D/F | 908 | |

| PSS4836-6B | CABINET 600 CFM BLOWER & BAG | 48” x 36” x 40” | 833 |

| PSS4836-6F | CABINET 600 CFM BLOWER & FILTER | 993 | |

| PSS4836-6FH | CABINET 600 CFM BLOWER. & HOPPER D/F | 1018 | |

| PSS4836-62C | CABINET 600 CFM C/W REV. PULSE D/C | 1233 | |

| PSS6036-9B | CABINET 900 CFM BLOWER & BAG | 60” x 36” x 40” | 1038 |

| PSS6036-9F | CABINET 900 CFM BLOWER & FILTER | 1258 | |

| PSS6036-9FH | CABINET 900 CFM BLOWER. & HOPPER D/F | 1283 | |

| PSS6036-92C | CABINET 900 CFM C/W REV. PULSE D/C | 1463 |

REQUEST MORE INFORMATION

Please fill out the form below and a Manus Sales Representative will contact you within 1 business day.

Thank you for contacting us.

A Manus sales representative will contact you within 1 business day.

Please try again later